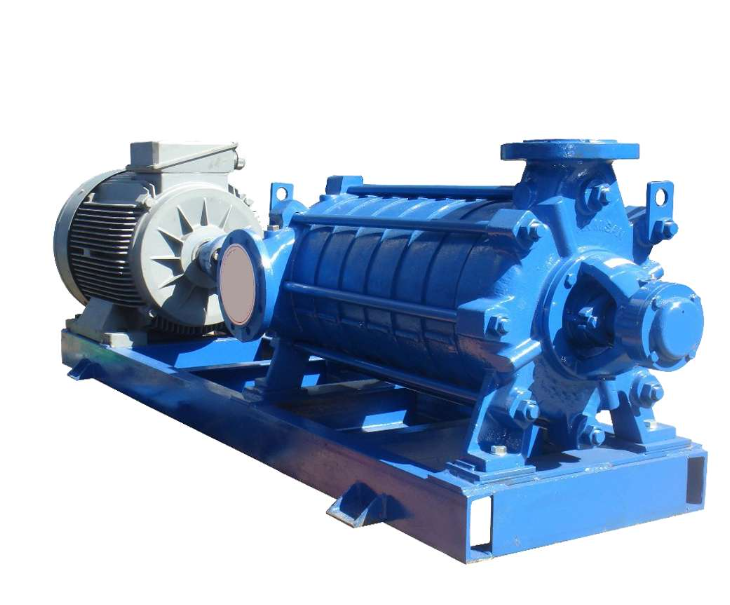

Electric Hydraulic Pump

Introduction:

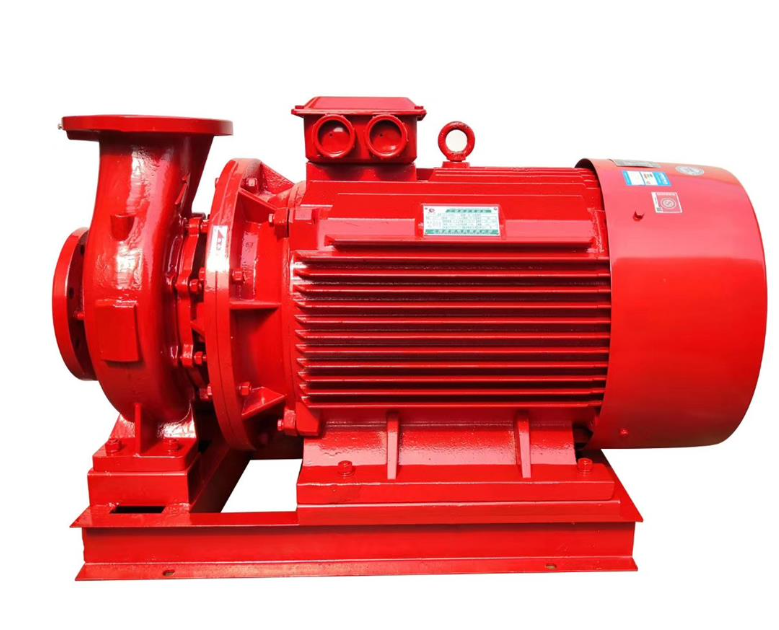

An electric hydraulic pump is a device that uses an electric motor to drive a hydraulic pump, which generates hydraulic pressure to power various hydraulic systems. It is widely used in industries such as construction, manufacturing, and automotive.

Working Principle:

The electric hydraulic pump consists of an electric motor, a hydraulic pump, a reservoir, and various control valves. When the electric motor is activated, it drives the hydraulic pump to rotate, which creates a suction force that draws hydraulic fluid from the reservoir. The hydraulic fluid is then pressurized and delivered to the hydraulic system through the control valves.

Advantages:

1. Efficiency: The electric motor provides a consistent and reliable power source, ensuring efficient operation of the hydraulic pump.

2. Control: The electric hydraulic pump allows for precise control of hydraulic pressure and flow rate, making it suitable for applications that require accurate and adjustable power delivery.

3. Safety: Electric hydraulic pumps are equipped with safety features such as overload protection and pressure relief valves, ensuring safe operation and preventing damage to the hydraulic system.

4. Versatility: Electric hydraulic pumps can be used in a wide range of applications, from small-scale operations to heavy-duty tasks, thanks to their adjustable pressure and flow rate capabilities.

5. Environmental-friendly: Compared to traditional hydraulic pumps powered by internal combustion engines, electric hydraulic pumps produce less noise and emissions, making them more environmentally friendly.

Applications:

1. Construction: Electric hydraulic pumps are commonly used in construction equipment such as cranes, excavators, and forklifts to power hydraulic systems for lifting, digging, and material handling.

2. Manufacturing: Electric hydraulic pumps are used in manufacturing processes that require precise control of hydraulic pressure, such as metal forming, stamping, and injection molding.

3. Automotive: Electric hydraulic pumps are used in automotive applications such as power steering systems, brake systems, and suspension systems to provide the necessary hydraulic power.

4. Maintenance and Repair: Electric hydraulic pumps are essential tools for maintenance and repair tasks, such as hydraulic system testing, cylinder and valve actuation, and hydraulic equipment operation.

Maintenance:

To ensure the proper functioning and longevity of an electric hydraulic pump, regular maintenance is required. This includes:

1. Checking and replacing hydraulic fluid regularly to maintain proper lubrication and prevent contamination.

2. Inspecting and cleaning the pump's filters to remove debris and maintain optimal flow.

3. Checking and tightening all connections to prevent leaks and ensure proper operation.

4. Regularly inspecting the motor and pump for any signs of wear or damage and replacing any faulty components.

5. Following the manufacturer's guidelines for maintenance and service intervals.

Conclusion:

The electric hydraulic pump is a versatile and efficient device that plays a crucial role in various industries. Its ability to provide precise control, safety features, and environmental friendliness make it a preferred choice for powering hydraulic systems. Regular maintenance is essential to ensure its optimal performance and longevity.